How to Select the Right Wood Glue for Your Project

_720.jpg)

In woodworking, the quality of your glue can be just as important as the wood itself. The right adhesive not only ensures a strong bond but also affects the longevity and appearance of the finished product.

At Midwest Dowel, we understand that whether you're working with dowel rods, plugs, craft, and toy parts, or other turnings, selecting the right wood glue is crucial.

This article will guide you through the various types of wood glues available and help you determine the best fit for your specific project involving Midwest Dowel’s products.

.png)

Understanding Wood Glue Types

Wood glue comes in several formulations, each designed for specific applications and wood types. The most common are PVA (Polyvinyl Acetate), Polyurethane, Epoxy, Hide, and CA (Cyanoacrylate) glues.

PVA Glue:

PVA glue, often known as white glue or carpenter’s glue, is a popular choice for general woodworking. It’s easy to use, non-toxic, and provides a strong bond. PVA glue is ideal for indoor projects, such as assembling furniture with dowel rods from Midwest Dowel or attaching wooden plugs for a smooth finish.

Polyurethane Glue:

This type of glue is known for its strong, waterproof bond, making it an excellent choice for outdoor projects or items that will be exposed to moisture. Polyurethane glue expands as it cures, filling in any gaps. It works well for joining Midwest Dowel’s outdoor furniture components or garden decorations.

Epoxy Resin:

Epoxy is a two-part adhesive, consisting of a resin and a hardener that must be mixed before use. It’s waterproof, extremely strong, and effective on a variety of materials. Epoxy is suitable for complex projects involving Midwest Dowel products, where a particularly strong or gap-filling adhesive is needed.

Hide Glue:

Traditional hide glue is made from animal products and is revered for its reversibility and natural composition. It’s a good choice for antique furniture restoration or musical instrument repair, where Midwest Dowel’s dowels and turnings might be used.

Cyanoacrylate (CA) Glue:

Commonly known as super glue, CA glue bonds quickly and works well on non-porous materials. It’s ideal for small repairs or craft projects involving Midwest Dowel’s small wood parts.

Selecting the Right Glue for Midwest Dowel Products

When working with Midwest Dowel’s range of wood products, consider the following factors to select the appropriate glue:

Strength Requirements:

Assess the strength required for your project. PVA glue is sufficient for most indoor projects, such as bookshelves or cabinets featuring Midwest Dowel’s dowel rods. For items that bear more weight or stress, like chairs or bed frames, consider a stronger adhesive like epoxy or polyurethane glue.

Moisture Exposure:

For outdoor projects or items that will be exposed to moisture, waterproof or water-resistant glues are a must. Polyurethane glue or waterproof PVA formulations are ideal choices for outdoor furniture pieces using Midwest Dowel’s products.

Open Time:

Different glues have varying open times (the time before the glue starts setting). Consider how much time you need to assemble your project. For complex assemblies using multiple dowel rods or turnings, glue with a longer open time might be necessary.

Clamping Time:

Clamping time refers to how long the glued pieces need to be clamped together before the bond is strong enough to hold without support. This factor is crucial when working on larger projects with Midwest Dowel’s products, where it might not be feasible to clamp for extended periods.

Ease of Use and Cleanup:

PVA glue is easy to work with and cleans up with water, making it a great choice for beginners or quick projects. Polyurethane glue, on the other hand, requires acetone for cleanup and can be messier due to its expansion.

Aesthetics:

Consider the final appearance of your project. Some glues dry clear, while others might leave a visible line. For fine furniture or decorative pieces using Midwest Dowel’s dowels and turnings, an adhesive that dries clear or can be easily sanded and stained is preferable.

Safety:

Always factor in safety, especially if working in a poorly ventilated area or if you have sensitivities to certain chemicals. PVA and hide glues are generally safer and more environmentally friendly options.

.png)

Application Tips:

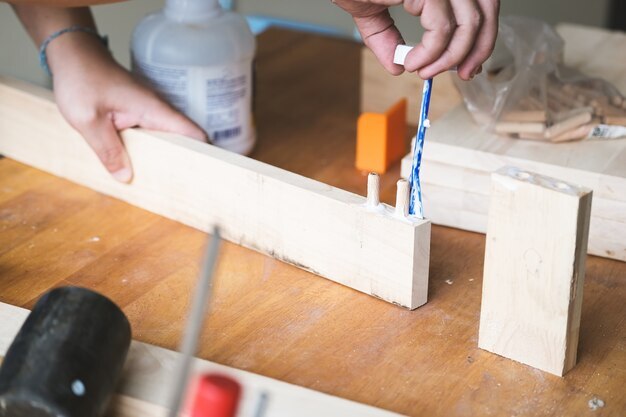

Applying glue correctly is as important as choosing the right type. Here are some tips for working with different Midwest Dowel products:

- Surface Preparation: Ensure that the surfaces to be glued are clean, dry, and free of dust and oil. For dowel joints, make sure the dowel fits snugly in the hole.

- Applying Glue: Apply glue evenly but avoid excess, which can weaken the bond or ooze out, marring the appearance. For dowel joints, apply glue to both the hole and the dowel for a stronger bond.

- Clamping: Proper clamping ensures a tight bond. Use enough pressure to close the joint but avoid over-tightening, which can squeeze out too much glue and weaken the joint.

- Drying Time: Respect the recommended drying time for the glue you’re using. Rushing this process can compromise the strength of the bond.

Select the Perfect Wood Glue for Your Projects with Midwest Dowel

Selecting the right wood glue for your project is a crucial step in ensuring the longevity and quality of your work. Whether you’re creating a masterpiece with Midwest Dowel’s dowel rods, securing plugs for a seamless finish, or crafting with small wood parts, understanding the properties and uses of different glues will guide you to a successful outcome.

Remember, the strength of your project lies not just in the wood but also in the bond that holds it together. Choose wisely, apply carefully, and your wood creations will stand the test of time.

For more wood tips follow Midwest Dowel on Facebook, Instagram, Twitter, and Pinterest!

Happy with the Midwest Dowel difference? Leave us a five-star review here!

Do you need dowels for your next project? Click here to shop Midwest Dowel today!